Tungsten

[W, WK, WTh, WCe, WLa]

W, WK, WTh, WCe, WLa

At around 3420 °C, tungsten has the highest melting point of all metals. By adding suitable alloying elements, its physical, chemical and mechanical properties can be adapted in many ways. Pure and alloyed tungsten is used in the lighting industry, electronics, medical technology and thin-film technology, as well as for welding electrodes and the construction of high-temperature furnaces.

W / WK1 / WK2 / WK3

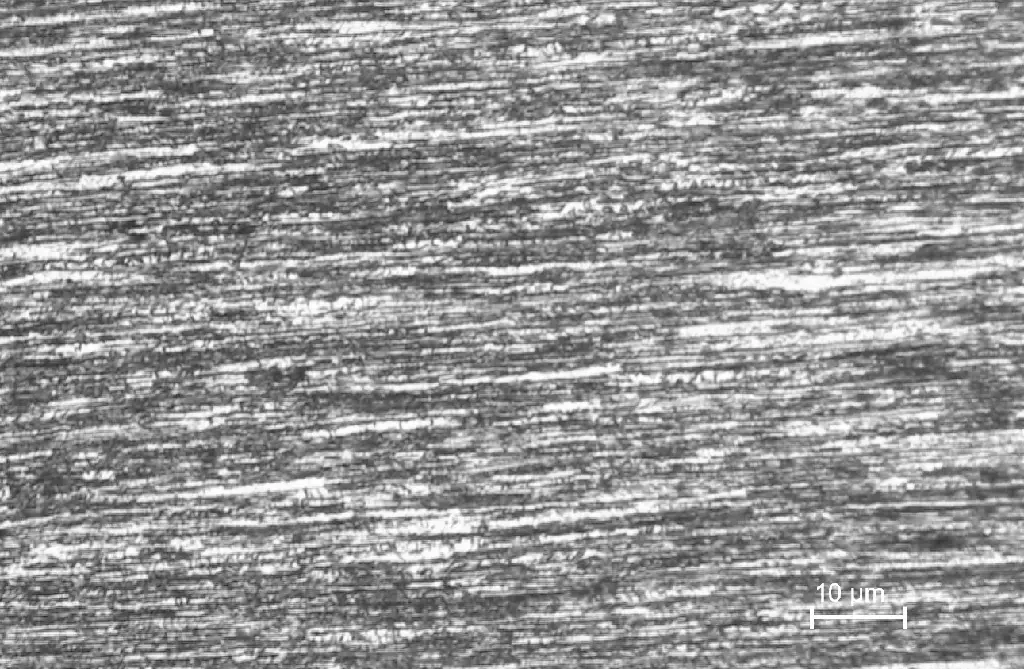

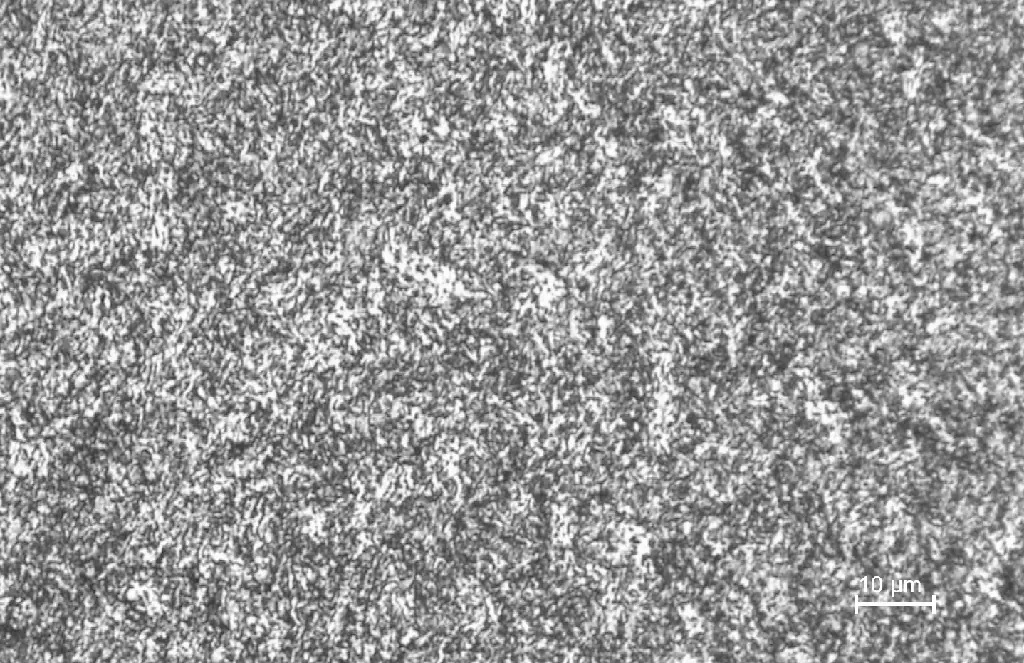

Tungsten doped with traces of Al, K and Si (in ppm ranges) is mainly produced in the form of rods and wires. This targeted doping in combination with a strongly directed deformation leads to a longitudinally oriented grain structure that significantly improves the material properties. This results in a higher recrystallization temperature, improved deflection strength at high temperatures and increased corrosion resistance to molten metals. Pure tungsten (W) and doped tungsten (WK) are widely used as single or multiple wires in evaporation coils and heating elements. In addition, W/WK rods and pins are used in lamp electrodes and stationary anodes for X-ray diagnostics.

WTh20 / WTh10

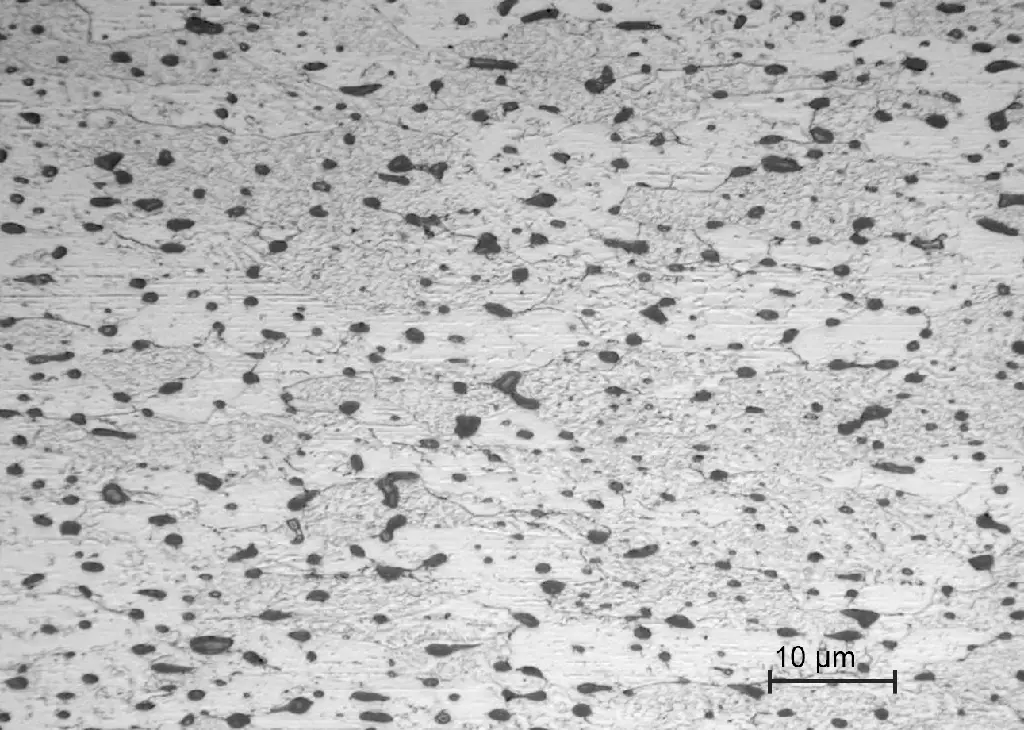

The addition of thorium oxide (ThO2) improves creep resistance and reduces electron work function, making these materials ideal for highly stressed cathodes. WTh10, which is doped with 1% by weight ThO2, can be drawn into wires with a diameter of ≤ 0.3 mm. The more heavily doped WTh20, on the other hand, is used for larger diameter rods.

WCe20

WC20 is an alternative to the WT20 lamp and welding electrode. The addition of 2 percent by weight of cerium(IV) oxide reduces the electron work function and improves both the ignition behavior and the service life by reducing the erosion rate due to spark erosion.

WLa10 / WLa15 / WLa20

The addition of 1 – 2.5% by weight of lanthanum oxide increases the creep strength and recrystallization temperature compared to pure tungsten. In addition, the oxide particles in the structure help to eliminate the poor machinability of pure tungsten. The addition of lanthanum oxide also significantly reduces the electron work function.

WLa10 is preferred for machined components in a variety of applications, such as ion source components and lamp electrodes, while WLa15 and WLa20 are mainly used for welding electrodes.

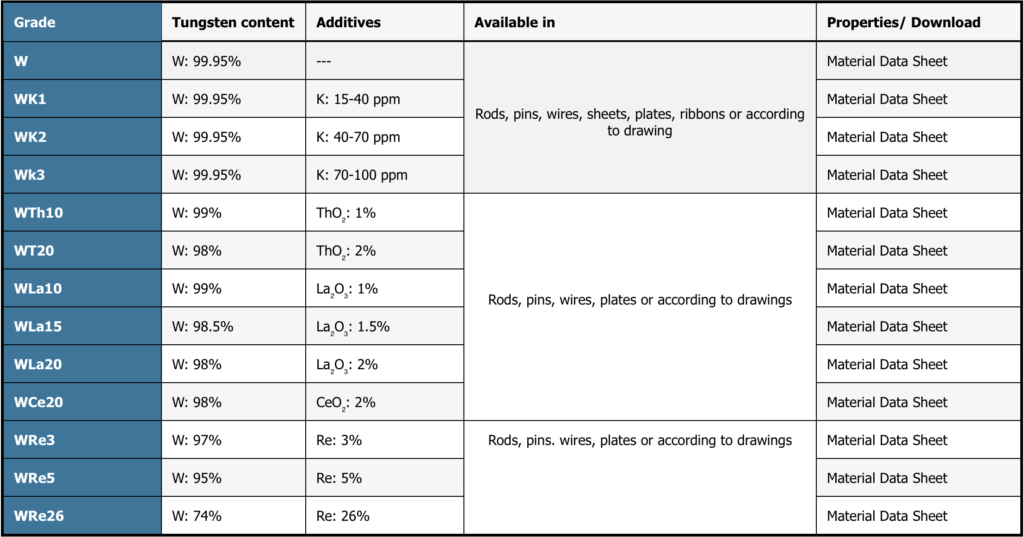

Product selection and material properties

We supply the following material alloys as standard grades

Grade | Tungsten content | Additives | Available in | Properties/ Download |

W | W: 99.95% | --- | Rods, pins, wires, sheets, plates, ribbons or according to drawing | |

WK1 | W: 99.95% | K: 15-40 ppm | ||

WK2 | W: 99.95% | K: 40-70 ppm | ||

Wk3 | W: 99.95% | K: 70-100 ppm | Stäbe, Stifte, Drähte, Bleche, Platten, Bänder oder gemäß Zeichnung | |

WTh10 | W: 99% | ThO₂: 1% | Rods, pins, wires, plates or according to drawings | |

WT20 | W: 98% | ThO₂: 2% | ||

WLa10 | W: 99% | La₂O₃: 1% | ||

WLa15 | W: 98.5% | La₂O₃: 1.5% | ||

WLa20 | W: 98% | La₂O₃: 2% | ||

WCe20 | W: 98% | CeO₂: 2% | Stäbe, Stifte, Drähte, Platten oder gemäß Zeichnung | |

WZr3 | W: 99.7% | ZrO₂: 0.3% | Stäbe, Stifte, Drähte, Platten oder gemäß Zeichnung | |

WZr8 | W: 99.2% | ZrO₂: 0.8% | Stäbe, Stifte, Drähte, Platten oder gemäß Zeichnung | |

Metallography

Specifications and standards

- ASTM F288 (Tungsten wire for elctron devices and lamps)

- ASTM F269 (Standard Test Method for Sag of Tungsten Wire)

- ASTM B760 (Tungsten Plate, Sheet, and Foil)

- ASTM F73 (Tungsten-Rhenium Alloy Wire for Electron Devices and Lamps)

- ASTM E696 (Tungsten-Rhenium Alloy Thermocouple Wire)

- DIN EN ISO 6848 Arc Welding and Cutting - Non-consumable Tungsten Electrodes

Delivery program

Rods, bars, wires, sheets, electrodes, plates, strips and finished parts according to customer drawings

Inquiries / Orders

Do you have any questions or would you like to place an order?

Feel free to contact us!

E-Mail: [email protected]

Phone: +49 (0) 8131 3164192