Grades & data sheets

| Variety | Composition | Density | Electrical conductivity | Thermal conductivity | Available as | Data sheet |

|---|---|---|---|---|---|---|

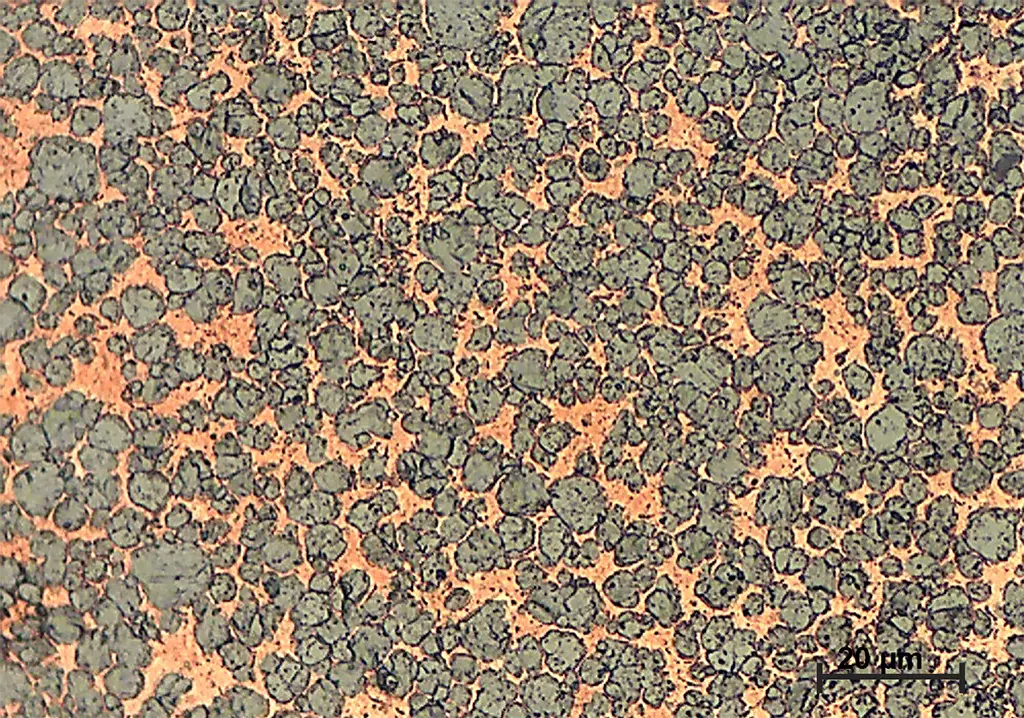

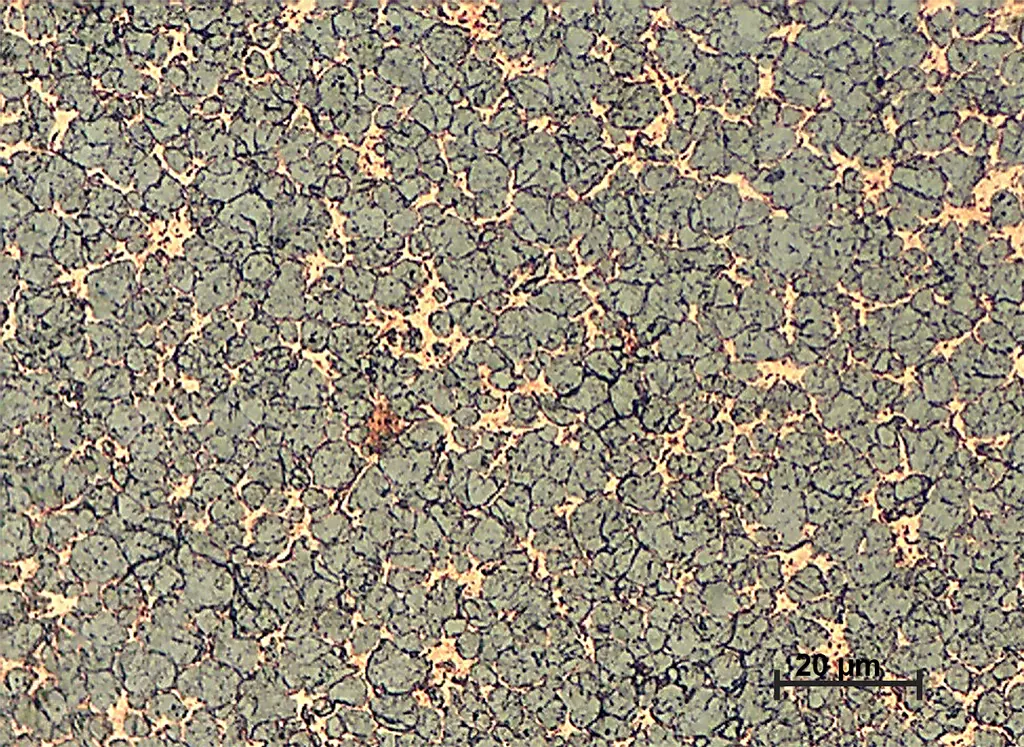

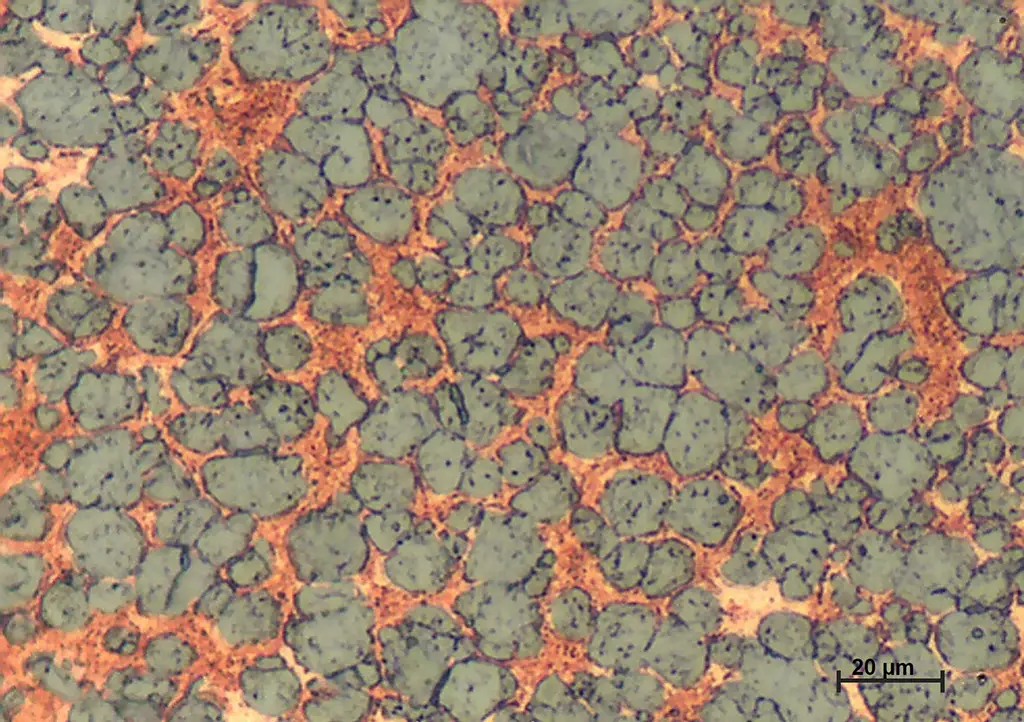

| WCu 50/50 | W 50% / Cu 50% | 12.0 ± 0.3 g/cm³ | ≈ 60 % IACS | ≈ 220 W/m-K | Discs, rods/bars, plates, tubes, finished parts | On request |

| WCu 60/40 | W 60% / Cu 40% | 13.0 ± 0.3 g/cm³ | ≈ 54 % IACS | ≈ 210 W/m-K | Discs, rods/bars, plates, tubes, finished parts | On request |

| WCu 70/30 | W 70% / Cu 30% | 14.0 ± 0.3 g/cm³ | ≈ 48 % IACS | ≈ 180 W/m-K | Discs, rods/bars, plates, tubes, finished parts | Material data sheet |

| WCu 75/25 | W 75% / Cu 25% | 14.7 ± 0.3 g/cm³ | ≈ 44 % IACS | ≈ 170 W/m-K | Discs, rods/bars, plates, tubes, finished parts | Material data sheet |

| WCu 80/20 | W 80% / Cu 20% | 15.3 ± 0.3 g/cm³ | ≈ 41 % IACS | ≈ 165 W/m-K | Discs, rods/bars, plates, tubes, finished parts | Material data sheet |

| WCu 90/10 | W 90% / Cu 10% | 17.2 ± 0.2 g/cm³ | ≈ 40 % IACS | ≈ 160 W/m-K | Discs, rods/bars, plates, tubes, finished parts | On request |

Density: 14.7 g/cm³

Thermal conductivity: 170 W/m·K

Electrical conductivity: ≈ 40-60 % IACS (depending on variety) S/m

Supply programme

Do you need further information?

Questions? We’re happy to help.

Contact us — we provide tailored solutions.