Key benefits at a glance

Technical properties

| Reinheit | up to ≥ 99.95 % (depending on material) |

|---|---|

| Schmelzpunkt | depending on material (up to 3,400 °C) |

| Dichte | depending on material |

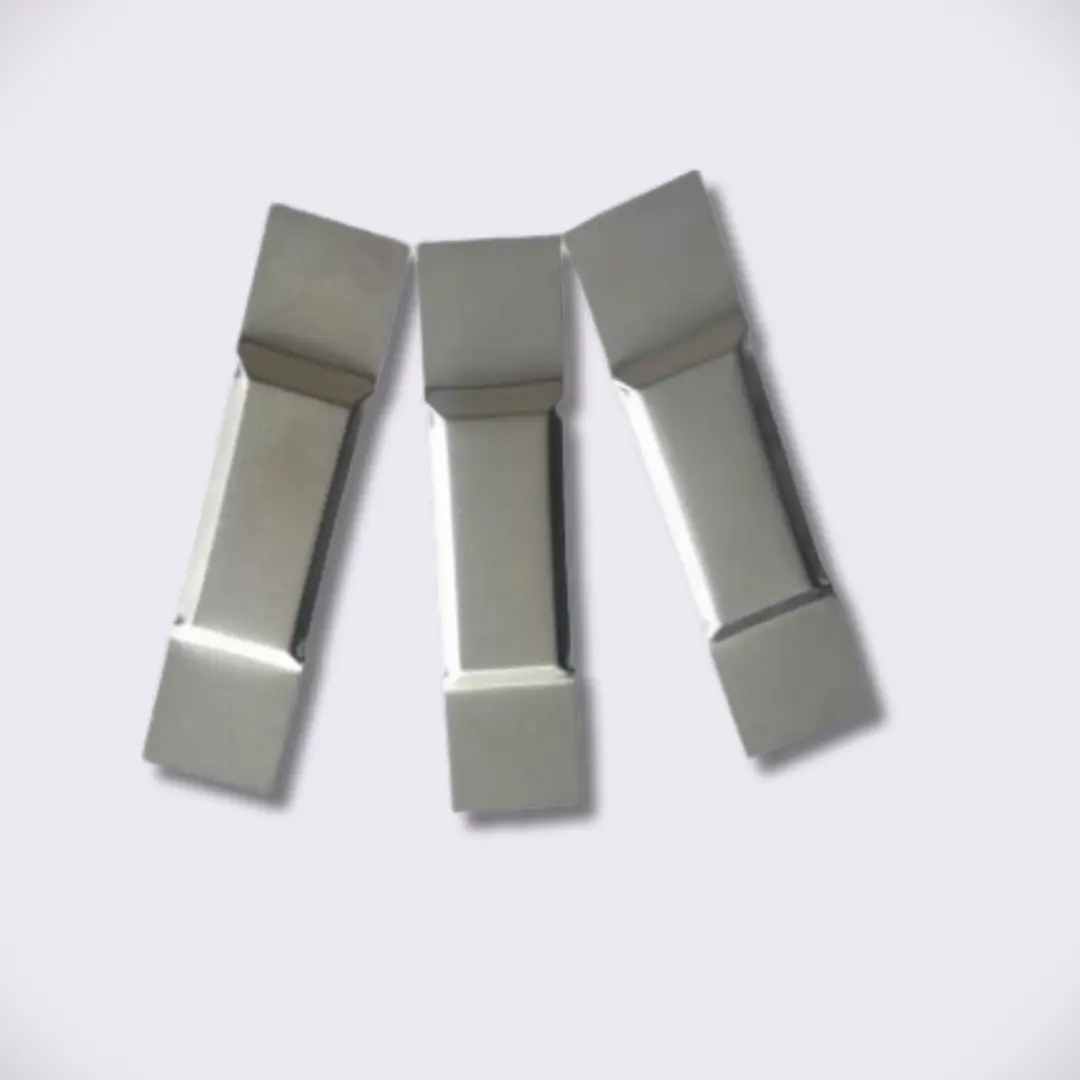

| Lieferformen | Evaporation boats, coils and crucibles in standard or special shapes according to drawing |

Why Molytun

Molytun supplies leading companies worldwide in industry & research

As a specialized partner for Wolfram and Molybdän, we provide more than just metals: we deliver top quality, fast response times, and solutions that precisely match your requirements.

Global network

We supply customers worldwide and ensure reliable availability – even for large requirements.

Made in Germany

Wolfram products manufactured in Germany: high precision, verified quality, and production to the latest standards.

Stock availability

Thanks to efficient logistics and large inventory, many products are available immediately. For fast and reliable supply.

Customized delivery

Whether powder, semi-finished products, or components – we deliver exactly to your technical specifications.

Our materials in application

Wolfram and Molybdän are key materials for future technologies. From medical technology to semiconductors and aerospace – our products meet the highest requirements across a wide range of industries.

We look forward to hearing from you and are available at any time for questions or requests.

Start your special metals projects – we will get back to you within 24 hours.

Head office

Gaußstr.10

85757 Karlsfeld

Germany