Grades & data sheets

| Variety | Composition | Density | Hardness (HV10) | E-modulus (GPa) | Electrical conductivity (% IACS @20 °C) | Available as | Data sheet |

|---|---|---|---|---|---|---|---|

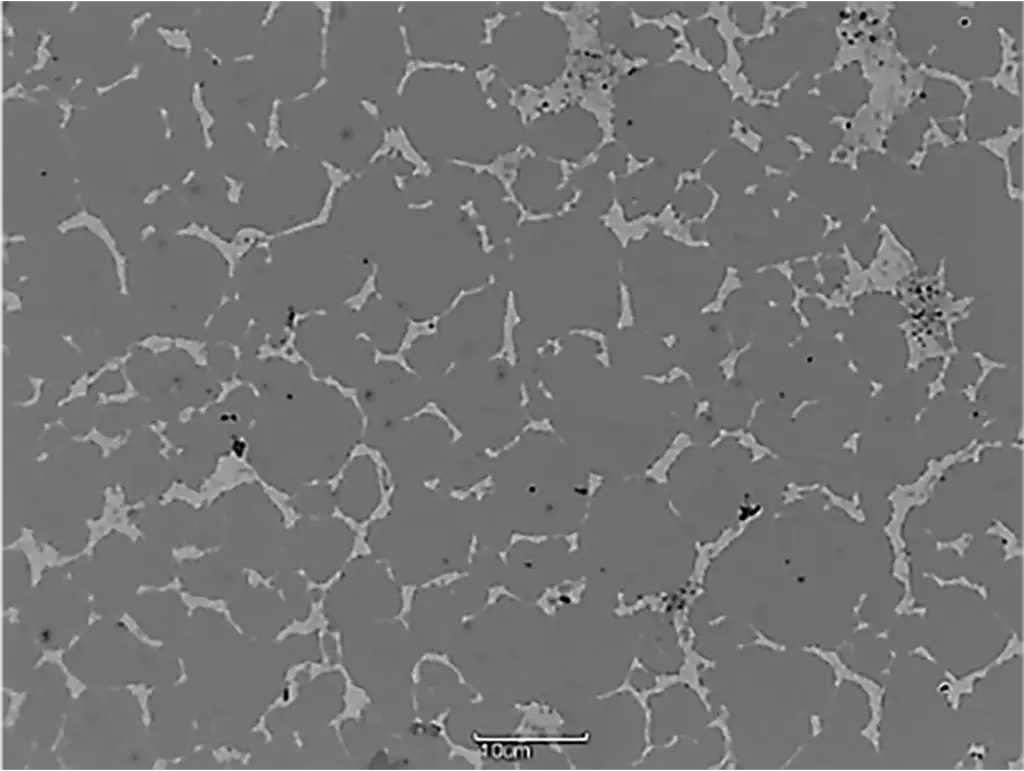

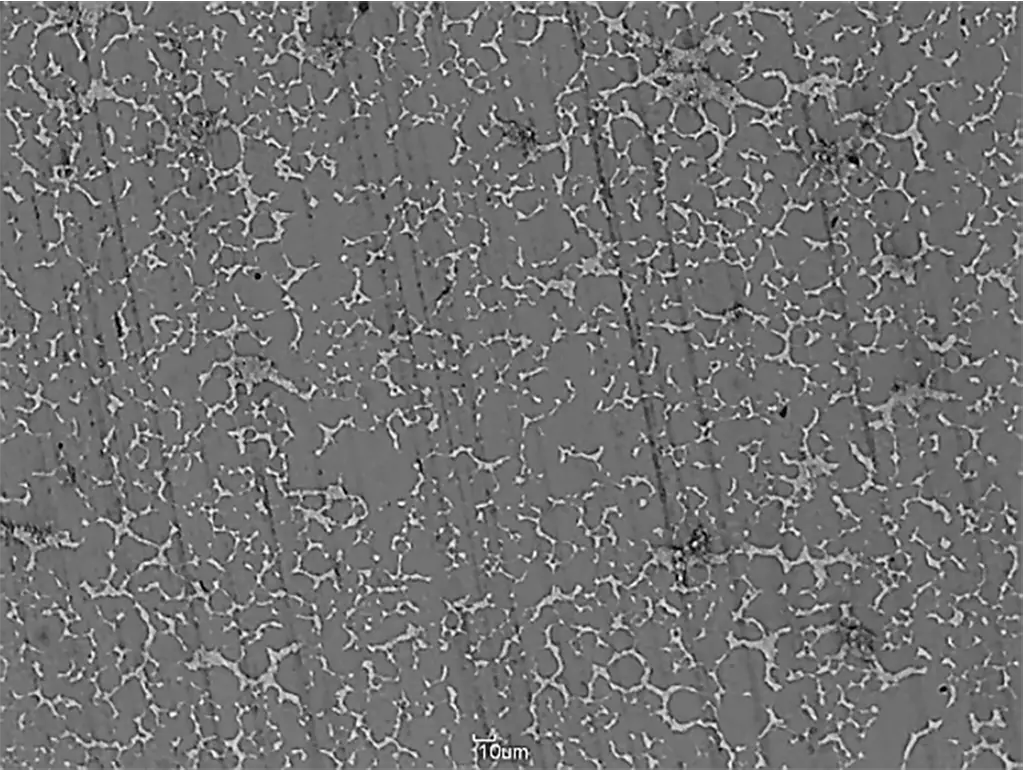

| WAg 50/50 | W 50% / Ag 50% | 13.6 ± 0.3 g/cm³ | 90 ± 30 | 190 ± 20 | 62 ± 3 | Rods, bars, plates, tubes, finished parts | Material data sheet |

| WAg 65/35 | W 65% / Ag 35% | 14.9 ± 0.3 g/cm³ | 130 ± 30 | 240 ± 20 | 53 ± 3 | Rods, bars, plates, tubes, finished parts | Material data sheet |

| WAg 70/30 | W 70% / Ag 30% | 15.2 ± 0.3 g/cm³ | 170 ± 20 | 250 ± 20 | 50 ± 3 | Rods, bars, plates, tubes, finished parts | On request |

| WAg 75/25 | W 75% / Ag 25% | 15.5 ± 0.3 g/cm³ | 210 ± 30 | 270 ± 20 | 45 ± 3 | Rods, bars, plates, tubes, finished parts | Material data sheet |

Density: 15.0 g/cm³

Electrical conductivity: ≈ 45-62 % IACS (20 °C, depending on variety) S/m

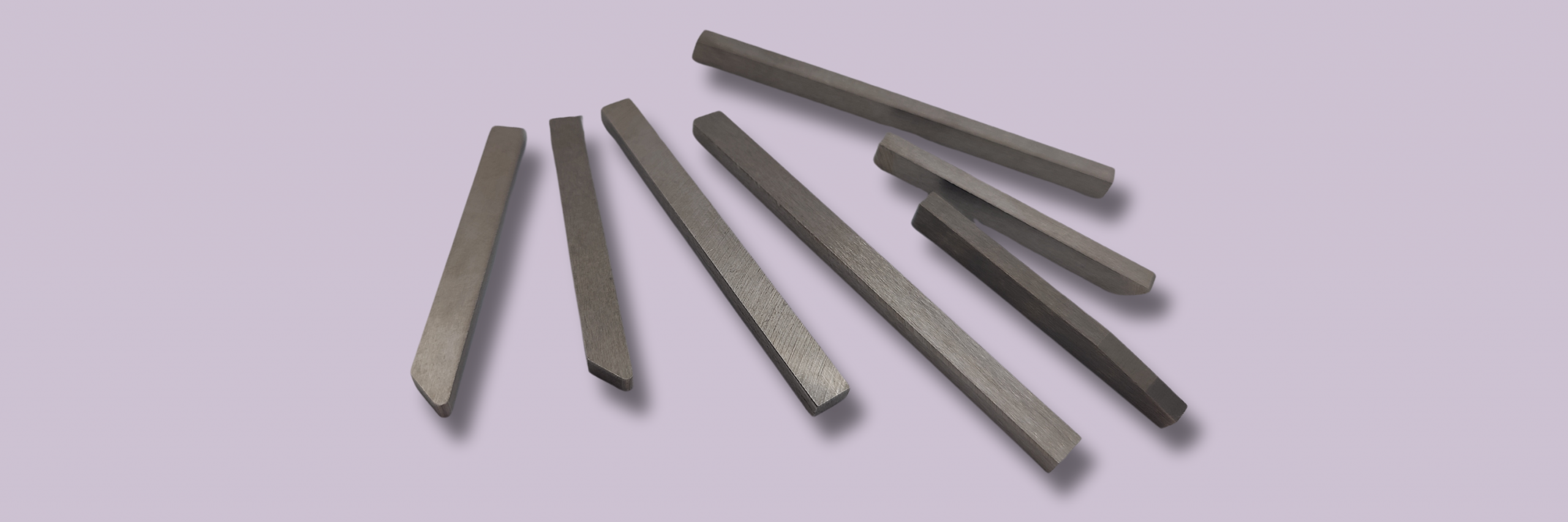

Supply programme

Do you need further information?

Questions? We’re happy to help.

Contact us — we provide tailored solutions.